KVS Run-Around Energy Saving System

- Categories:产品

- Time of issue:2020-06-18 00:00:00

- Views:0

|

|

|

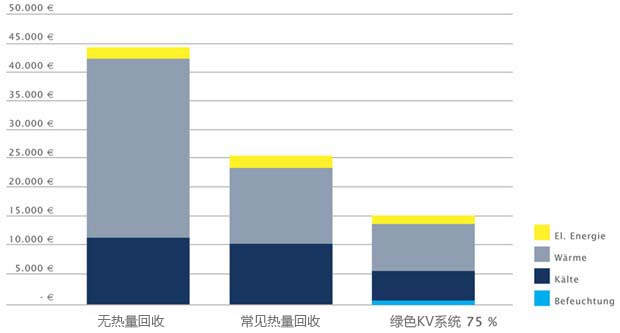

Responsibility and energy saving

|

|

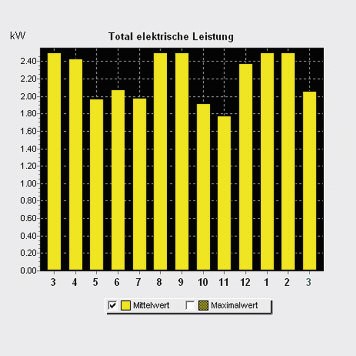

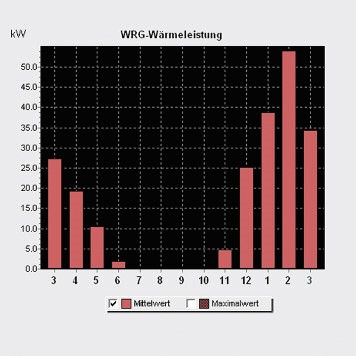

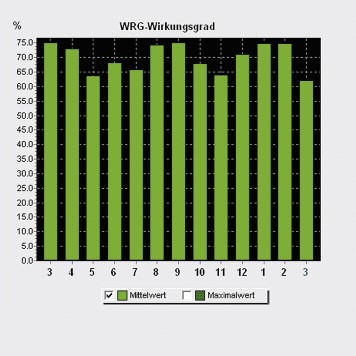

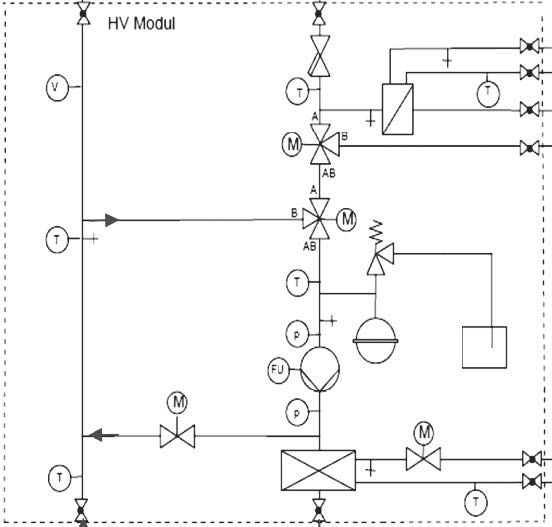

Understand how the system works

|

|

Responsibility and energy saving

|

Understand how the system works

|

Scan the QR code to read on your phone

Contact person

If you have any questions, please contact:

Marketing Assistant

(+86)512 5656 5656

info@huber-ranner.cn

Service

Even if we have delivered the equipment, we are still on call to bring you flexible and convenient services and provide personalized and comprehensive services.

Page Copyright © 2023 HUBER&RANNER Environmental Equipment (Taicang) Co., Ltd. Powered by www.300.cn 苏ICP备16063255号-1